Siporex Projects

SIPOREX Has Been certified on Large-Scale Projects such as Housings, Schools, Hospitals, Commercial, Industrial and Government Projects Under All Different Climatic Conditions

Environmentally Friendly

SIPOREX is a Natural and Non-Toxic Construction Material, Saves Energy, and is Friendly to the Environment.

Revolutionary Material

SIPOREX is a High Quality Structural Material, Load-Bearing and Extremely Well Insulating Material due to Numerous Tiny Non-Connecting Air Bubbles which gives SIPOREX its Incredibly Diverse Qualities

Why Choose Us

Why SIPOREX ?

- LCC-Siporex has more than 45 years’ experience in the field of AAC construction. And accomplished huge number of successful projects.

- A Technical team for projects studies to give the projects optimum workable solutions.

- An Engineering team with high qualifications specialized in Structural Analysis using the most updated Finite element Analysis software.

- A Supervision team to control and supervise the site works activities and keep the work with high quality and fast progress.

- LCC-Siporex has three factories, So there will be no shortage or late production. This will control the project delivery to follow the client requirements.

- All the products of LCC-Siporex are updated and complied with the latest related national / international standards and codes.

Lightweight Construction Company

Here in the Kingdom of Saudi Arabia, LCC Siporex was established in 1976 and has been producing Siporex – Autoclaved Aerated Concrete (AAC) material at our plant in the Riyadh Second Industrial Estate, Al Kharj Road, Riyadh

See MoreOur Products

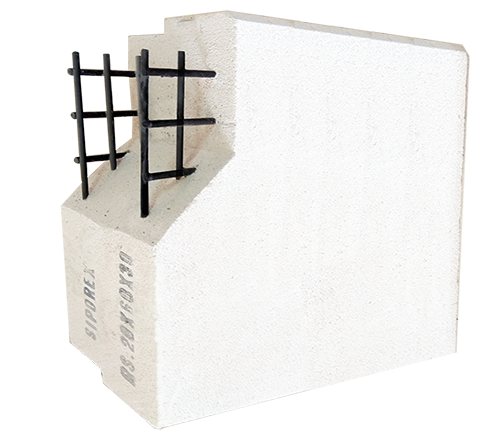

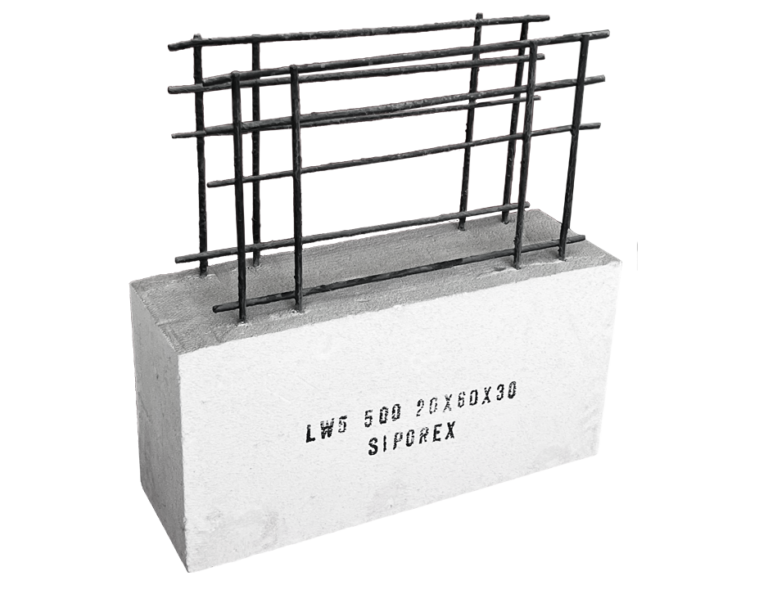

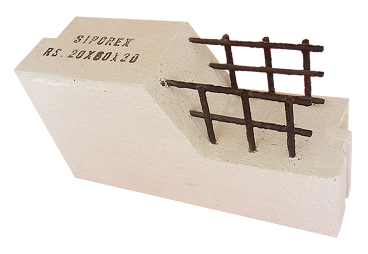

Reinforced Panels

Steel Reinforced Siporex Panels are produced in different types such as: Wall Panels, Lintels, Roof and Floor Slabs.

Our Products

Blocks

Siporex solid blocks are used as load-bearing and non load-bearing walls and as thermally insulating roof tiles in addition to being used as Hordi blocks or infills for ribbed slabs. They are produced with very precise dimensions with slim tolerance of ±3mm for thickness and width, therefore they are able to be laid by thin-bed mortar (Siporex glue) with a maximum of 3mm thick mortar joint. This results to a high quality wall structure with uniform thermal insulation and fast installation.

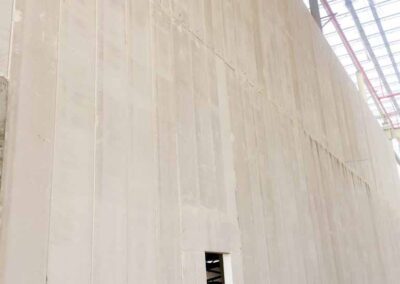

Our Projects

Project Gallery

Our Partners